At last, the rubber price is improving; the event we have long waited for but we do not know for how long it will last. The growers had to undergo a long frustrating period with rubber, as far as the price is concerned and therefore, it is not unreasonable or wrong to get the full benefit of the prevailing high price. But we should never forget that we have once experienced all this some time back and we must learn lessons from past experience.

Rubber price

By mid-2011, the price of a kilo of rubber reached unbelievably and unrealistically high Rs.625.00 and lasted for a short period. But that short period was long enough to do permanent damage to many rubber fields in the country.

Unfortunately, many farmers did not know of the consequences of excessive tapping. Just to get the advantage of the high price prevailed, farmers tried to harvest as much as latex from the trees, without paying any attention to the tapping quality or tapping frequency.

It is an open secret that some rubber fields in the Kaluthara district were tapped twice daily instead of once in two days. Many fields were tapped daily. During the short period, a high crop was recorded and good profits were made.

Another thing that happened unintentionally and unknowingly was the increase in the cost of production. In other words, during that period, no one wanted to keep rubber trees untapped. Getting a rubber tapper to tap an abandoned rubber field was not easy and needed a lot of persuasions and it was costly.

With compared to the selling price, a high wage for the tapper was possible and affordable. Accordingly, those who claimed that they could tap rubber trees were also employed in tapping without paying any attention to their experience or tapping quality.

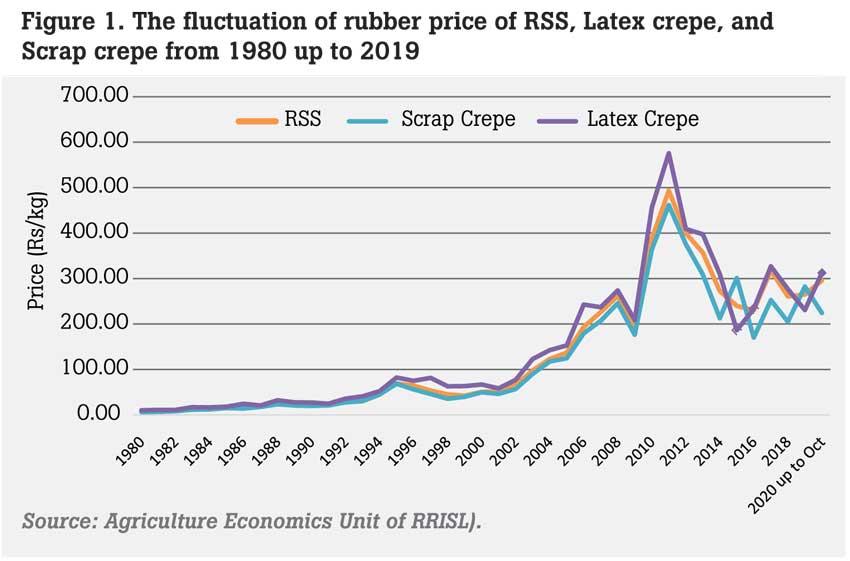

The price of any commodity fluctuates within a range. Similarly, the rubber price slowly declined and the crop too was reduced gradually as the trees were stressed.

Soon the farmers had to face the bitter reality. They ended up with a low price and poor crop. Though we all are aware that this is a man-made situation for the rubber industry, we soon forget the past and do the same mistake any number of times. The biggest damage happened with this high price, though prevailed only for a few months, even Rs.400.00 is considered as a low price, though we can never predict such a high price again.

The fluctuation of rubber prices during the past four decades is shown in Figure 1. It is very clear from the Figure that the price during the period from 2008 to 2014, fluctuation is out of the normal track. As discussed, this created more negative results than beneficial impacts on the sustainability of the rubber industry.

The main objective of writing this is to talk about the consequences faced after the previous price hike in 2011 and prevent the same thing from happening again.

Harvesting rubber tree

The economical life span of a rubber tree is about 30 years. The tree needs about five years to grow into the harvestable size of 50cm girth measured at 120cm from the ground and when a field has more than 70 percent of such trees the harvesting commences. However, the number of years that the trees can be taped or the economical life span depends on the tapping system or frequency of tapping.

At each tapping, 1/20” (1.25 mm) thick bark shaving is removed. Therefore, if the frequency is high, i.e. more tapping days per year, then the bark consumption will be high.

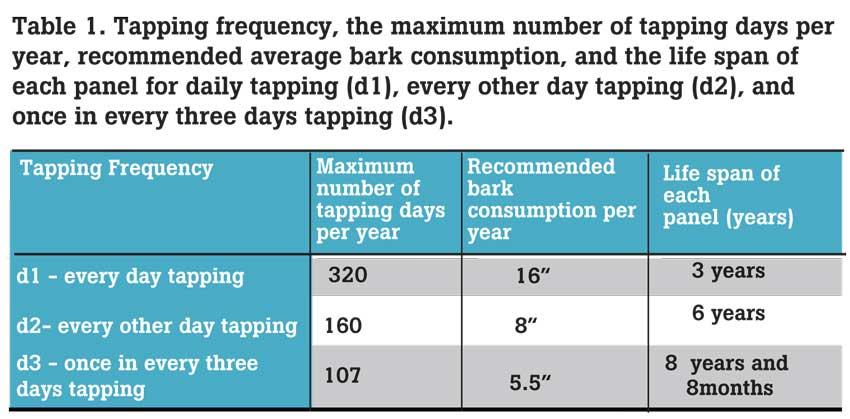

The average bark consumption and the life span of each panel are given in Table 1 for daily tapping (d1), every other day tapping (d2) and once in every three days tapping (d3).

Generally, only one half of the rubber tree is tapped at any given time, known as S/2 and under every other day tapping i.e. d2, one half of the tree or one panel can be tapped for six years for many clones. But there are some clones known as d3 clones, as the recommended tapping system for such clones is d3.

Clones like PB 260, a foreign clone recommended in group one in the current list of recommended clones is a d3 clone. Also, the clone RRISL 217 was recommended as d2 but after some years it was recommended to be tapped at d3 frequency, as the dry tree percentage was high.

Since the present-day rubber cultivation has all high-yielding clones such as RRIC 100, RRIC 102, RRIC 121, RRISL 203 and RRISL 2001, etc. the frequency of tapping is the most important factor which determines the sustainability. The highest tapping frequency recommended for these clones is d2 or every other day tapping with no yield stimulants.

However, if a d2 clone is tapped at d3 or d4, i.e. once every three days or once every four days, then a yield stimulant can be applied to get the same yield as d2 with no stimulation. But if the clone is a d3 clone such as PB 260 and RRISL 217, they should never be stimulated to tap at d3.

If your field has a d2 clone and tapped at d2 or d3 frequency with ethrel stimulation, never exceed the ethrel concentration or the application frequency in order to increase the yield. More importantly, such fields that are converted to low-frequency systems should never be tapped at normal d2 frequency. By doing any of the malpractices mentioned, you will be able to see an increase in the crop but it is very temporary and the negative impact or the damage is permanent.

However, as it is clear from Table 1, trees can be tapped longer with low-frequency tapping. In other words, the economical or commercial life span can be lengthened with low-frequency harvesting. As it is recommended by RRISL already, the clones that are recommended at d2 can be tapped at a lower frequency with an added advantage of the lesser requirement of tappers by about 33 percent as each tapper can be given three blocks compared to two in d2 tapping.

The most important factor to be considered in adopting low frequency is to adhere to RRISL recommendation and to make sure not to exceed the potential yield of the field. The potential yield of the field can be lower than the potential yield of the clone, due to the poor growth condition of the trees.

Tapping panel dryness ‘brown bast’

Tapping panel dryness is a physiological disorder, often a permanent state of bark becoming dry due to single or many factors, the main being over-exploitation. Unlike in 2011, rubber clearings today consist of a very high percentage of dry trees already and the condition of rubber fields is far below the expected standards.

Agro-management practices are not up to the standards or recommended levels in the majority of fields and this too has contributed to the current poor state of rubber fields. Accordingly, productivity also is far below the potential productivity of clones. As a result, most of the rubber fields are not profitable.

The present-day rubber clearings cannot afford to have any more dry trees as we have already exceeded the maximum percentage of dry trees a clearing could have. About 5-10 percent of dry trees are acceptable even during the first panel, due to the presence of week trees or runts and as a result of many factors. The dry tree percentage generally increases with the increase of the tapping years and that is also acceptable to some extent.

Excessive tapping

The Rubber Research Institute of Sri Lanka conducted an islandwide survey on bark consumption covering over 5000 ha in the 2010-2011 period. The results gathered through the survey were alarming and shown in Figure 2. The deviation of the life span of A and B panels varied from five to six years and only about 6 percent of the clearings had 12-13 years, as recommended and 0.8 percent showed 13-14 years.

Had this rate continued, there would not be rubber fields to harvest now. The Plantation Ministry intervened to assist the Rubber Research Institute to harvest on base panels until the correct position is reached and a quarter uppercut namely CUT (Control Upward Tapping) was introduced until then.

Training programmes for the rubber development officers, rubber extension officers and mainly the field staff and managers of estates under Regional Plantation Companies were done extensively during this period on bark auditing and tapping quality.

As for COVID-19 for human beings, tapping panel dryness can be avoided in rubber plantations by proper adopting recommendations on harvesting. It is not a high flaunting technique but simply to get the maximum crop for a longer period without harming the tree.

Statistics and rubber productivity

Rubber productivity is one of the key performance indicators to measure the sustainability in rubber plantations. This figure is drawn by dividing the total rubber production in the country for a particular year by the mature tapping extent. If any of these values are wrong, the productivity will be wrong.

Unfortunately, in Sri Lanka, no one reassures these figures and all are groping in the dark and take decisions on these figures. For instance, the statistics available on rubber production and the productivity calculated based on them are as in Table 2.

As can be seen from Table 2, there is no valid reason for the 38.8 million kg gap between 2013 and 2014, which is about 25 percent of the crop of 2013. Mainly due to this reason, the rubber productivity figure is down by 331 kg in 2014 than that in 2013, which is about a 26 percent reduction.

However, these statistics are ambiguous as the productivity changes from year to year cannot be explained with the available factors. For instance, the reasons for the sudden reduction of the crop as mentioned before are not known.

However, the productivity of individual estates and smallholdings determine the sustainability of the rubber industry in the country. They are free from the national average. The variation of the productivity of rubber lands is so high in both the Regional Plantation sector and the smallholder sector.

There are rubber fields giving about 750 kg/ha/y and on the other extreme 3000 kg/ha/y. When productivity is very low, the owners of such fields cannot survive and cry for a high price. On the other hand, the owners of fields giving very high productivity make profits even at a minimum price of rubber but the number of fields giving high crop, i.e. above 2000 kg/ha/y, is low.

The main reasons for low productivity are poor stand, poor growth condition of trees, the presence of dry trees, poor tapping quality, etc. Out of these, only the tapping quality can be corrected in a mature rubber clearing.

Monitory loss due to excessive tapping

Excessive tapping is a total loss and what we have observed in the tapping experiments is that when the number of tapings per year is lower, the crop per tapping is high. Accordingly, high frequency taping will never contribute to high profits but the other way round.

Moreover, the direct impact due to the loss of bark can be explained as follows: assuming,

The average productivity is 1000 kg/h/y and the average life span of a virgin panel due to excessive taping is four years (evident by the data collected).

Accordingly, the number of years lost per panel is two years and on two virgin panels, it is four years.

Therefore, the crop loss is 1,000 kg x 4 y = 4,000 kg/ha.

The yields on renewed bark is severely affected when virgin panels are consumed earlier than recommended six years. The bark renewal is incomplete and the expected crop loss is due to partial bark renewal is 20 percent, which is 1,600 kg (200 kg x 8 years).

The crop loss due to high bark consumption on renewed panels (if each panel is consumed in four years) 1,000 kg x 4 years = 4,000 kg.

The total crop loss = 9,600 kg/Ha (4,000+1,600+4,000).

If the rubber price is Rs.300/kg, the value of rubber lost is Rs.2,880,000.00 (9,600 kg x Rs.300.00) per hectare. This should be considered as the profit lost per hectare of rubber land as the cost of production will remain the same.

Way forward

Most of the rubber clearings in the country are in a very poor state and the productivity levels are low. If the reasons for low productivity are poor stand or substandard growth of the trees, then such fields are beyond recovery or rehabilitation. Also, due to various reasons, mainly the price, replanting did not take place as per the recommended rate of 3.3 percent for the past five to six years. Therefore, fields that have exceeded the economic lifespan also exist. If about 10 percent of unproductive fields are replanted, adopting all recommended planting practices of the Rubber Research Institute to guarantee 2500-3000 kg/ha/y now, in five to six years’ time, the rubber industry is sure to be blooming.

Planting material production needs one year nursery period and a sudden doubling of planting material requirement demands proper planning. The use of high-quality planting material is the most important factor in determining productivity. Clone plays a little when the plant quality is poor.

Similarly, the existing neglected rubber fields below two years of age should be given full attention to bringing to productive levels by infilling vacant points with similar aged plants and providing a full dose of fertiliser to boost the growth. Rubber trees girth only during the first five years of age.

If the reason for vacant patches is the white root disease infections, then such areas should be properly rehabilitated before infilling. At present, according to the estimates, about 5-10 percent of rubber fields are infected with this deadly disease and recommended methods should be followed to eradicate the pathogen. Soil preparation and conservation are equally or more important as fertilising as present-day rubber lands consist of very degraded and infertile soil.

By adopting all recommended agro-management practices and high-quality plants, productivity can be increased to 2500-3000 kg/h/y to make good profits even at the lowest rubber prices. Otherwise, the rubber industry cannot survive with the ever-increasing cost of production.

Rubber tree not only produces latex but its current extent of 134,000 ha contributes to the depleting forest cover of the country while cleaning the air to breathe and cooling for us to live. The flora and fauna harbour in rubber fields protect the rich biodiversity of the country.

Food for thought

The concept of a rubber home garden is looking at rubber plantations from a different perspective, to expand rubber cultivation without additional land requirement. There is no minimum number of trees for a person or a given place. When grown in isolation, rubber trees grow massively and give very high yields.

Ten to 20 rubber trees in the home garden or as the fence would give a sufficient crop that can be used as a supplementary income in their retiring age. Rubber will become the smallholders’ crop in the years to come with no overhead costs or staff to manage.

True smallholder farmers, who engage in on-farm activities using family labour, prefer rubber cultivation to other plantation crops. Easy and less demanding maintenance of rubber fields along with risk-free permanent income, attracts the interests of these farmers

As far as productivity of rubber lands in Sri Lanka is concerned, the seedling plantations in the first few generations could yield only about 300 kg/ha/year. The improved clones recommended and planted today have the potential productivity to give about 3000 kg/ha/year, which is a tenfold increase.

In many South East Asian countries, including Sri Lanka, the smallholder’s share dominates the rubber production of the country and continues to grow. The much larger estates managed by Regional Plantation Companies are burdened with overhead charges and increased labour wages and hence enjoy lower profits.

The present mechanism of allocation of subsidy and then deducting the cost of plants from it, is time-consuming, cumbersome, leads to corruption and the outcome is not favourable. Instead, if high-quality plants and the full dosage of fertiliser required during the immature phase of four to five years are made available for any interested person to grow rubber, a cultivation subsidy would not be necessary to persuade the farmers to grow rubber.

The key factors that contribute to the increase in rubber productivity in Sri Lanka are the use of high-quality plants and the maintenance of good standards of immature upkeep, especially the proper application of the correct dosage of fertiliser. Therefore, productivity improvement can be achieved by this method, with no additional effort, cost or intricate mechanisms.

When plant production in rubber nurseries is done with a commercial interest, the production and issuing of poor-quality plants become an inevitable consequence. The productivity of the plantations that are grown with such poor-quality plants cannot be increased and the latex production and profits become severely affected.

Since the smallholder farmers are the ones who will be buying plants from private nurseries, this problem is equally applicable to all rubber growing countries, where the share of smallholder farmers is on the increase. Hence, the government has a responsibility to invest judiciously in perennial crops like rubber, especially to make available only superior quality planting material, preferably given free of charge to the growers than paying subsidies in cash and charging the cost of plants later.

To further strengthen the rubber industry in Sri Lanka in a way that would support the economy of the country, innovations especially to increase value addition for rubber is of prime importance. Also, technology adoption in cultivation programmes through novel techniques such as social media are areas of interest.

(Dr. Priyani Seneviratne, Deputy Director Research (Biology), the Rubber Research Institute of Sri Lanka, Dartonfield, Agalawatta, can be reached via

[email protected])

At last, the rubber price is improving; the event we have long waited for but we do not know for how long it will last. The growers had to undergo a long frustrating period with rubber, as far as the price is concerned and therefore, it is not unreasonable or wrong to get the full benefit of the prevailing high price. But we should never forget that we have once experienced all this some time back and we must learn lessons from past experience.

At last, the rubber price is improving; the event we have long waited for but we do not know for how long it will last. The growers had to undergo a long frustrating period with rubber, as far as the price is concerned and therefore, it is not unreasonable or wrong to get the full benefit of the prevailing high price. But we should never forget that we have once experienced all this some time back and we must learn lessons from past experience.