15 May 2024 - {{hitsCtrl.values.hits}}

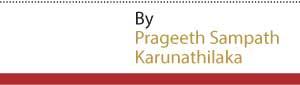

The picture shows one of the beams of the highway after it collapsed

The construction of the phase from Kottawa to Pinnaduwa- of the project titled ‘Expressway Network of Sri Lanka’- was completed in 2011. During its construction, a medical student died as a result of a minor collapse of a bridge on the expressway in 2008. This incident sparked widespread concern regarding the quality and reliability of this expressway facility. Although the concept of expressways was relatively new to Sri Lankans at that time, there was significant discourse regarding passenger safety; particularly in the event of a bridge or culvert falls apart while the facility is being used for travel. Investigations later confirmed that the cause of the collapse was the improper construction of the bridge.

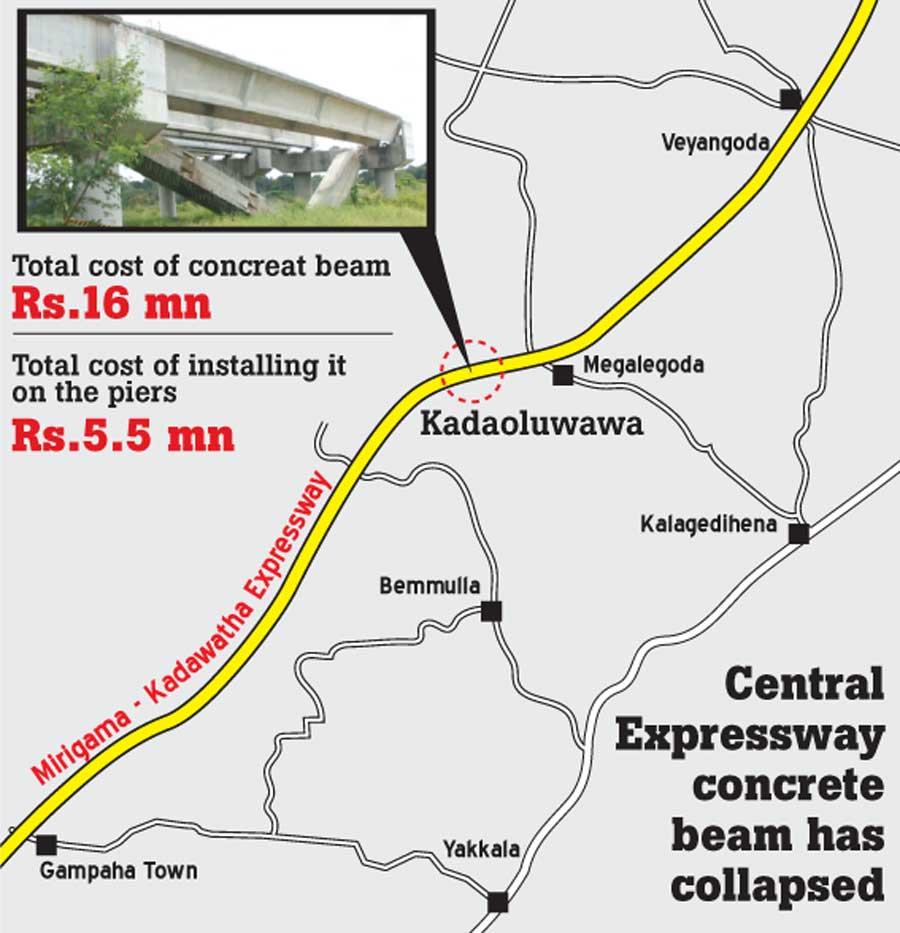

The other beams at a 45 degree angle are unaffected by the collapse of one beam

On May 4, another incident occurred that instilled fear in people about traveling on these expressways. A massive concrete beam collapsed in the 18.1 km section of the Central Expressway, stretching from Kadawatha to Mirigama. The concrete beam that collapsed was part of the section of the expressway that is being constructed on piers between Magalegoda and Bemmulla. This 36.59 km stretch from Kadawatha to Mirigama is being developed as the first phase of the Central Expressway project.

Expressway, stretching from Kadawatha to Mirigama. The concrete beam that collapsed was part of the section of the expressway that is being constructed on piers between Magalegoda and Bemmulla. This 36.59 km stretch from Kadawatha to Mirigama is being developed as the first phase of the Central Expressway project.

It was decided during a cabinet meeting, held on July 8, 2015, that the then Ministry of Highways, Ports and Shipping, now known as the Ministry of Highways, along with the Road Development Authority (RDA), would oversee the implementation of this project. However, Metalogical Corporation China (MCC) was ultimately selected to carry out the project. The estimated budget for this endeavour was 196,174 million rupees. The project was scheduled to commence on December 29, 2016 with its completion scheduled for August 31, 2020.

Accordingly, the Government of Sri Lanka (GoSL) decided to obtain a loan from the EXIM Bank of China for this project. According to the loan agreement if 365 days pass without construction work being commenced the agreement between the government and EXIM Bank will automatically be terminated. The construction of the first phase of the highway, initially slated to commence in 2016, did not begin until June 2020. Subsequently, the initial construction work halted once more in 2022.

The collapsed concrete beam was installed at that location in 2021. However, before even three years had passed and prior to the completion of the expressway’s construction it collapsed. This raised concerns about the quality of the Central Expressway. Though this facility being constructed by a Chinese company, the project was supervised by the RDA. In this large-scale project, every process, from soil filling to other activities, undergoes testing and reports are obtained accordingly. Specifically, the concrete mixture used for each concrete beam- placed on the expressway- is tested separately in a laboratory and reports are obtained. According to the reports, beams are only utilized for construction if the concrete mix meets quality standards. Based on the laboratory report, one can find details regarding the quality of the collapsed beam.

Who will take responsibility?

If these concrete beams are used without thorough inspection, the question regarding who will take responsibility arises. It remains unclear whether the construction company, the RDA, or the Government of Sri Lanka will assume accountability in the case of a mishap. Regardless, it is evident that these expenditures stem from the tax contributions of the country’s citizens.

It costs about 16 million rupees to produce one concrete beam and an additional 5 1/2 million rupees to install it on the piers from where it was manufactured. Ultimately, the total cost for each beam comes close to 22 million rupees. The other problem is that when the beam fell to the ground, two other nearby beams twisted and tilted to one side as a result. Consequently, those two beams cannot be used again. As a result of this accident, three concrete beams of the Central Expressway have been destroyed; incurring a loss of nearly 66 million rupees. Furthermore, approximately 6 km of this road has been constructed using concrete beams on piers. If these beams also prove to be of poor quality, the total loss could amount to billions of rupees. The issue of who bears this loss remains unresolved.

According to RDA officials the expressway hasn’t been transferred yet from MCC to the RDA as construction is in progress. The RDA has determined that the company (MCC) should bear the loss. If MCC was to claim that the quality of construction and the collapse resulted due to delays on the part of the GoSL in completing the expressway on time, then the government would have to bear the loss.

The 6 km stretch, constructed using concrete beams on piers, is currently undergoing testing. The quality of that section of the highway can only be determined after completion of the tests. Additionally, according to the agreement between this company (MCC) and the GoSL, the work will proceed. “Even though at present, the RDA insists that they refuse to bear the loss and instead MCC should do so, we are skeptical whether we will ultimately bear the loss. A good example from the past is worth mentioning. A ship carrying contaminated fertilizer from China was anchored in Sri Lankan waters for months and was later returned at a cost of 6.9 million dollars. It was claimed that good quality fertilizer would be provided in return. However, no such shipment arrived, resulting in the loss of the entire 6.9 million dollars. It would not be surprising if a similar situation was to occur regarding Chinese concrete beams.

The 6 km stretch, constructed using concrete beams on piers, is currently undergoing testing. The quality of that section of the highway can only be determined after completion of the tests. Additionally, according to the agreement between this company (MCC) and the GoSL, the work will proceed. “Even though at present, the RDA insists that they refuse to bear the loss and instead MCC should do so, we are skeptical whether we will ultimately bear the loss. A good example from the past is worth mentioning. A ship carrying contaminated fertilizer from China was anchored in Sri Lankan waters for months and was later returned at a cost of 6.9 million dollars. It was claimed that good quality fertilizer would be provided in return. However, no such shipment arrived, resulting in the loss of the entire 6.9 million dollars. It would not be surprising if a similar situation was to occur regarding Chinese concrete beams.

When this newspaper inquired about this incident from Nalinda Ratnayake, Project Director RDA- which oversaw the first phase of the Central Expressway-stated, “The collapsed concrete beam weighs about 80 tons. We are investigating the cause of the collapse. This beam was manufactured in 2021, and according to its laboratory reports, it was made meeting the proper standard. If there were any issues with the concrete, it would have collapsed earlier. This involves technical design and utilising a separate technology from the cables used for it. It’s not like manufacturing a regular beam; it’s a complex process.

“Presently, we have determined that the collapse of this beam occurred due to an issue connected with the rubber pad installed between the concrete pier and the beam during its installation. Additionally, we found that the rubber pad got exposed to sunlight and rain which caused its quality to deteriorate after three years; hence the gradual tilting of the beams. The beam is shaped like a ‘T’, with vehicles driving over the top horizontal part of the letter ‘T’. The load is then transferred to its lower part and distributed to the ground, as per the design. This design works similar to a bow. Therefore, when a beam collapses, it fractures,” Ratnayake said.

“It costs about 16 million rupees to manufacture this beam and approximately 5.5 million rupees to install it. When everything is completed, the total cost will be around 22 million rupees. This beam is manufactured by MCC itself, and its creation is part of our ongoing study. Two beams that are currently tilted need to be removed. If a beam tilts more than 45 degrees, it can crack. Therefore, it has been decided to remove all three beams. This project has not yet been handed over to the RDA. Consequently, the Chinese company itself must bear the loss and reinstall three beams. If it is our project, the Sri Lankan Government will be responsible for the losses. However, this scenario does not apply here. The beams are placed at a distance of 6 km, and we are conducting separate inspections of those bridges and beams.

“They cannot hold us (RDA) responsible for the delay in the construction of the Central Expressway because this is a contractual obligation carried out in accordance with the law. If the MCC makes such claims we would have to take legal action. However, it’s unlikely that the company would pursue this route due to their own numerous mistakes. We will reach the right conclusion once our investigations are completed,” Ratnayake added.

When this newspaper questioned MCC Project Director Subash Madushanka regarding these issues, he stated-during a telephone conversation- that no details had been uncovered regarding the collapsed beam.

This writer then approached Alfred Gajasinghe, Senior Engineer attached to the State Engineering Corporation of Sri Lanka, to discuss the fundamental principles of concrete beams, commonly used in expressway construction.

Gajasinghe said that he lacked knowledge about the contractual conditions or regulations between the contracting company and the government regarding the Central Expressway. However, he said that a brief explanation can be provided regarding the basic principles of project design which is common to any project.

“When constructing a road or expressway, it is designed according to the specifications provided by the relevant institutions regarding the type and speed of vehicles travelling on it. Following this, quality control and assurance measures should be implemented during the actual construction phase. It includes procedures starting with soil filling and the types of concrete utilised and the specific cables employed. Subsequently, the contracting company should receive separate consultation. Some contracting companies provide that consulting service. I am not familiar with the specific procedures followed for the Central Expressway.

“When beams are utilised in a project like this, quality is essential. Valuable technical knowledge is offered from the construction of the beam’s fabrication to its installation. A small mistake could cause the beam to crack, which is a matter of concern, as people work in these environments. Hence, a follow-up inspection- after the installation process- should be carried out to ensure a proper job done and assess quality. However, I’m not sure if such procedures were implemented in this instance. This beam is fractured in the middle. It’s impossible that the fracture occurred due to its weight alone; considering the beam’s designed load-bearing capacity. If the collapse resulted from the failure of the two rubber plates installed on both sides, it indicates a problem with the quality of these components. May be poor quality rubber plates were used during installation because it was planned to encase the beam in concrete. Encasing the beam in concrete would protect the rubber plates from sunlight and rain. May be this happened because the beam was not encased with concrete. According to that, there seems to be an issue regarding whether adequate monitoring and supervision were carried out concerning the quality of the beams when installing them following the road design plan,” said Gajasinghe.

16 Jun 2024 2 hours ago

16 Jun 2024 2 hours ago

16 Jun 2024 4 hours ago

16 Jun 2024 4 hours ago

16 Jun 2024 4 hours ago